The Alfdex g-Cleaner™

Leading the way

in the green movement

The world’s No. 1 choice.

Today, the Alfdex g-Cleaner is established as the favorite solution for cleaning crankcase gases in combustion engines. Both on-road and off-road. Our client list includes all the major brands. The Alfdex g-Cleaner is currently installed in more than six million trucks worldwide. Providing living proof that even a small effort can have a substantial impact on the environment.

Designed for tomorrow.

The g-Cleaner meets all regulations regarding crankcase ventilation, including those of EURO 6 and EPA13, Stage 5 and Tier 4 Final. The g-Cleaner also fulfills the proposed EURO7 and EPA27 requirements. This means that if your engine is fitted with the g-Cleaner, you will be prepared for any forthcoming legislation, making you a green frontrunner. It will give you peace of mind as well as boosting your company’s sustainability image.

Driven by g-force.

The g-Cleaner is based on a proven century-old technology – the centrifugal separator developed in 1877 by the Swedish innovation genius Gustav de Laval. It has been adapted to fit modern combustion engines by the technical experts at Alfdex.

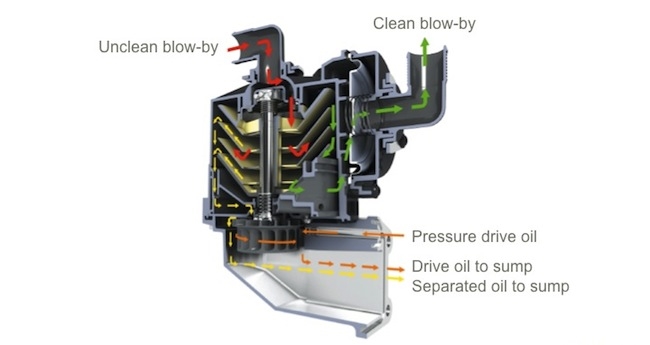

The g-Cleaner uses the centrifugal separation technique to prevent contaminated ventilated crankcase gases from returning to the inlet of combustion engines – or being emitted to the environment. The core of the process is a rotating conical disc stack. A turbine or an electric motor at the bottom of the centrifuge drives the disc stack at speeds of 7,000-9,000 rpm. Oil and soot particles are removed from the gas by means of centrifugal forces of about 2,500-3,000 g.

The centrifugal force makes the droplets and particles coalesce forming larger clusters that flow towards the outer edge of the discs. From there they are discharged onto the inner wall of the separator housing. The droplets and particles are then flown down to the bottom of the g-Cleaner, before finally being returned to the engine sump. Cleaned crankcase gases are either returned to the engine or emitted into the air.

Efficiency: close to 100 percent.

The cleaning performance of the present version of our g-Cleaner is as close to 100 percent you can achieve with existing technology. We are presently developing a new generation of the product with an electrified disc stack drive. The goal is to further enhance the innovative features of the g-Cleaner to meet new, even tougher environmental requirements. The California Air Resources Board, CARB, is setting tighter limits, which are likely to constitute a future benchmark. This new generation g-Cleaner is designed to improve energy efficiency and to maintain an extremely high cleaning capacity during a prolonged lifetime. To sum up: it will be a peak performer.

Flexibility of power.

The g-Cleaner can be driven either by oil or electricity, both of which provide high and stable efficiency and stability. The advantage of the oil-driven solution is that it can cleverly utilize the already existing engine oil infrastructure. In the electrically driven version, the g-Cleaner features a built-in, state-of-the-art, electrical motor and controller, which allow for precise separator speed management. The best option? The choice depends on the application you have.

For all types of fuel.

Traditionally, the g-Cleaner is mainly used in diesel engines. However, new fuels are presently being introduced at a rapid pace. When it comes to biofuels – liquid and gas – the g-Cleaner will likely be the preferred alternative for dealing with soot and hazardous particles in the coming 15 years. We see this as a growing business. Regarding hydrogen fuel, specially designed internal combustion engines are in the pipeline. To accommodate these, an adapted version of the g-Cleaner is currently being developed and pilot projects are underway.

Sustainable performance.

Once installed, a g-Cleaner offers a substantial reduction in oil emissions. Overall performance figures are impressive: year in, year out, some 100 million liters of oil is recycled thanks to the g-Cleaner installed in heavy truck engines worldwide. Virtually no oil is discharged from these trucks into the environment. No maintenance is required during the entire service life of the engine. The g-Cleaner is sealed for life. And the absence of waste products such as a filters eliminates the need for recycling. All for the benefit of the environment – and your engine, especially since the air entering turbocharges and intercoolers is not contaminated, allowing for peak performance.